Industrial Electrical Services & Testing

Keeping you up and running is our number one goal. Because downtime is never an option.

Performing both acceptance and maintenance testing on your electrical system is crucial in making sure that your system is running at peak performance. As a NETA certified company that specializes in these procedures, when you work with Power Products & Solutions, you're guaranteed to have an electrical system that won't let you down.

Monotonectally productize fully researched relationships, and compellingly fabricate interdependent e-markets. Phosfluorescently mesh fully researched information.

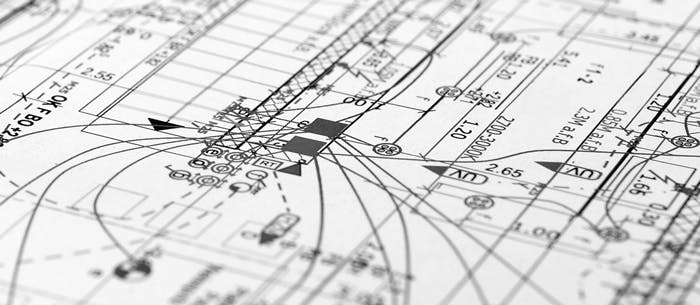

NETA ACCEPTANCE TESTING

With electrical systems and process equipment becoming more commonly integrated and difficult to start-up, the construction industry has adopted the practice of “Total Building Commissioning,” a systematic process of verifying, documenting and placing into service newly-installed, or retrofitted electrical power equipment and systems.

Commissioning is critical for all new or retrofit installation projects to verify the integrity of integrated and stand-along systems to assure they operate per design, thus contributing to the safe and reliable operation of the system.

If you need to verify the integrity of your integrated or stand-alone system, Power Products & Solutions is here to help. Learn More about Neta Acceptance Services.

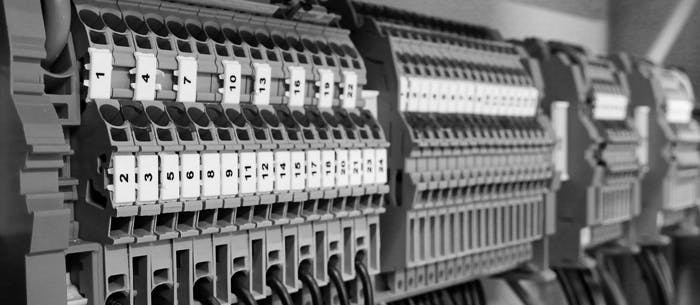

CIRCUIT BREAKER REPAIR

Every circuit breaker, transfer switch, panel board, and other piece of your vital electrical operations will, at some point, need to be repaired, retrofitted, or re-manufactured. The question is, how long will it take to get it done, and get it done right? Most importantly, how much will that downtime cost you?

Let us retrofit your power circuit breakers with AC-PRO solid-state trip devices. AC-PRO solid-state trip unit is a true RMS sensing overcurrent device that will reduce both nuisance trips and the downtime required for maintenance on your equipment.

Power Products & solutions can upgrade your low-voltage power circuit breakers and insulated case circuit breakers with the latest solid-state trip technology based on your specific needs. We also offer reconditioning and re-manufacturing of medium-voltage air and vacuum circuit breakers, motor controls, and contactors.

When you need repairs done quickly and efficiently, you need experts with over 30 years of experience in your corner. Our team is here to reduce your downtime and give you peace of mind that your systems are in the right hands. Learn More about Circuit Breaker Testing & Repair.

MV CABLE TERMINATIONS

MV (medium voltage) cable termination and testing is one of the top services that Power Products & Solutions offers; our team of skilled technicians has performed thousands, with peak expertise in this area.

Many customers tell us that one of their top concerns is the longevity of the medium voltage cables feeding into their facilities. This concern has prompted many plant and facility maintenance managers to include visual and mechanical inspections, and non-destructive testing of their MV cables on a more consistent basis. Our Tan Delta cable test set is designed to meet their IEEE medium voltage cable testing specifications and requirements.

We have performed Tan Delta testing for our customers with vintage MV cables and the results have been quite impressive. Using this method, we are able to:

- Find problems in cable terminations and splices

- Easily gather and record test data

- Use data to determine if cables have deteriorated since previous testing

- Determine the life expectancy of conductors

- Locate any problems before they wreak havoc on an electrical system

We are also proud of our numerous certifications including:

- 3M MV cable splicing and termination certification

- Raycham MV cable splicing and termination certified

- Richards MV cable splicing and termination certified

- NCSCB MV cable splicer certified

Contact us today to discuss our Tan Delta testing or any of our other MV cable testing services!

Learn More about MV Cable Testing Services.

EMERGENCY

SERVICE

Unexpected downtime due to loss of electrical power is not only expensive, but dangerous as well - it's the last thing you want to deal with. Power Products & Solutions will help make sure your facility is up and running quickly when you encounter an emergency. We'll also take the time to make sure your systems are running optimally to avoid further problems down the road.

Whatever type of equipment you have, we are here 24/7/365 to keep your operation running smoothly. Not near Charlotte or Greenville? No worries. We will travel across the country to help you get back on track as fast as possible.

Learn More about our Emergency Services.

Need help fast?

Let's Get Started Together.

Power Products & Solutions is proud to be a part of the Weisger Group.

A TRUSTED PARTNER IN YOUR SUCCESS.

.png&w=3840&q=75)

.png&w=3840&q=75)